What Are Custom ESD Foam Inserts?

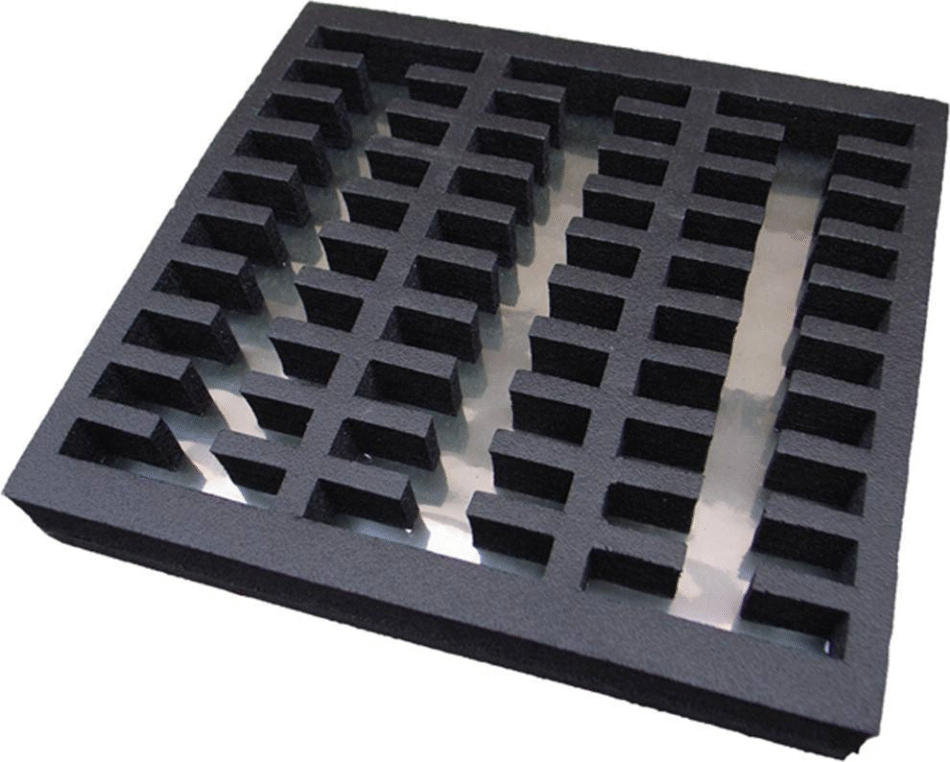

Custom ESD foam inserts are specially engineered packaging solutions designed to protect sensitive electronic components from damage caused by static electricity. These inserts are cut and shaped to match specific items and are crafted using materials that either prevent or neutralize static buildup.

They’re not your ordinary foam inserts. They’re precision-designed for industries where a single spark can ruin an entire batch of sensitive devices. From microchips to circuit boards, the stakes are high—and ESD foam makes all the difference.

In today’s manufacturing and distribution world, especially in electronics, protecting equipment from static shock is no longer optional. It’s a necessity.

Why Static-Sensitive Products Need ESD Protection

Even a tiny amount of static electricity—measured in volts—can permanently damage sensitive electronics. Static damage isn’t always visible; it can silently degrade components, causing failures later in the product lifecycle.

Top reasons static-sensitive products need ESD protection:

- Invisible threat: ESD cannot be detected without equipment.

- Component damage: From resistors to ICs, all can be ruined by static.

- Costly replacements: Damaged components increase production costs.

- Quality assurance risks: ESD issues can lower customer trust.

That’s where ESD foam inserts play a heroic role, safeguarding tech from assembly to delivery.

How ESD Foam Works

So, what’s the science behind it?

ESD foam is made using carbon or conductive additives that either dissipate or neutralize static charges before they harm the object. Unlike regular foam, which can generate or retain static, ESD foam redirects electrical charges away from sensitive items.

Three Functions of ESD Foam:

| Function | Description |

| Conductive Shielding | Channels electricity through the foam safely. |

| Dissipative Properties | Slowly bleeds off static charges from contact surfaces. |

| Anti-Static Nature | Resists static generation during handling or movement. |

These mechanisms ensure that even when moved or touched, the items remain protected.

Key Benefits of Using Custom ESD Foam Inserts

Let’s break down what makes ESD foam a no-brainer investment for static-sensitive environments.

- Tailored Fit: Foam is cut to the exact shape of the product.

- Static Protection: Prevents electrostatic discharge damage.

- Enhanced Durability: Keeps items in place during transit.

- Professional Presentation: Clean, uniform appearance.

- Reduced Returns: Minimizes damage-related customer complaints.

Bonus: They also help in keeping workstations organized!

Types of ESD Foam Used in Inserts

Conductive Foam

- Surface resistance: <10⁴ ohms

- Provides a quick path for static to travel

- Ideal for shipping ICs and microprocessors

Dissipative Foam

- Surface resistance: 10⁵ to 10⁹ ohms

- Slower static discharge, safer for certain sensitive components

- Common in assembly and storage environments

Anti-Static Foam

- Surface resistance: 10⁹ to 10¹² ohms

- Minimizes static generation, good for temporary storage

- Often used in workstation inserts

Each type serves a specific purpose and is chosen based on the product’s sensitivity.

Industries That Rely on Custom ESD Foam Inserts

- Electronics Manufacturing

- Aerospace

- Telecommunications

- Medical Equipment

- Automotive (EV batteries & sensors)

- Defense & Military

Wherever sensitive circuitry is involved, you’ll find custom ESD foam inserts quietly doing their job.

Comparing ESD Foam Inserts vs. Regular Foam Inserts

| Feature | ESD Foam Inserts | Regular Foam Inserts |

| Static Protection | ✅ Yes | ❌ No |

| Material Conductivity | Carbon or static-dissipative agents | Polyurethane or polyethylene |

| Cost | Slightly higher | Lower |

| Application | Electronics, sensitive gear | General packaging |

| Longevity in Clean Rooms | High | Low |

The added cost of ESD foam pays for itself in avoided damages and warranty claims.

Customization Options for ESD Foam Inserts

Foam Thickness and Density

Choose the right resistance to compression and vibration based on your product’s fragility.

Cavity Design and Layout

Tailor the layout to your assembly line or storage racks for better workflow and safety.

Color Coding and Identification

Use colored foam or printed labels to distinguish between product types or ESD zones.

Step-by-Step Process: Designing Your Custom ESD Foam Insert

- Product Assessment: Measure size, weight, and fragility.

- Material Selection: Choose between conductive, dissipative, or anti-static foam.

- Design Mock-up: Use CAD to visualize cavity placement.

- Prototype Testing: Evaluate for fit and static resistance.

- Production Run: Finalize design and proceed to batch manufacturing.

- Deployment: Inserts are placed in cases, trays, or cartons.

This process ensures your foam fits like a glove and performs as needed.

Best Practices for Handling and Maintaining ESD Foam Inserts

- Keep inserts clean and dry.

- Avoid sharp tools near foam cavities.

- Store in a static-controlled environment.

- Use ESD gloves or wristbands when handling.

- Inspect regularly for damage or wear.

Environmental Considerations and Sustainability

Custom ESD foam is recyclable in many forms, especially cross-linked polyethylene (XLPE) and EVA foams. Companies are now adopting closed-loop recycling systems to reduce landfill impact.

For example, ESD Journal covers the latest in ESD-safe recycling technologies.

Also, reusability of foam inserts over multiple cycles helps in reducing waste.

Common Mistakes to Avoid When Using ESD Foam Inserts

- Using regular foam instead of certified ESD foam

- Placing ESD foam in high-moisture environments

- Mixing ESD-safe items with non-compliant materials

- Not grounding foam when required

- Failing to replace old or worn foam

One small oversight can lead to huge repair or replacement costs.

Real-World Applications and Use Cases

- Semiconductor shipments: Thousands of chips moved without a scratch

- Medical diagnostics kits: Protected from static during airport scanning

- Aerospace sensors: Safely transported across international borders

- Defense communication devices: Stored in harsh environments with no ESD issues

Whether it’s a fragile PCB or a sensitive optical sensor, ESD foam keeps it protected.

FAQs

1. Are ESD foam inserts reusable?

Yes, many ESD foams are durable and reusable if handled properly.

2. Can I use ESD foam for storage as well as shipping?

Absolutely. Many organizations use ESD foam for both transit and long-term storage.

3. What’s the difference between conductive and dissipative foam?

Conductive foam quickly channels static charges; dissipative foam slowly neutralizes them.

4. Is it okay to use ESD foam without grounding?

In some cases yes, but for critical components, grounding enhances safety.

5. Does ESD foam degrade over time?

Yes, especially if exposed to moisture or UV light. Check your foam regularly.

6. Can I customize foam shapes for irregular items?

Yes! Custom cutting technology allows for nearly any shape or design.

Conclusion: Safeguarding the Future with Smart Foam Solutions

Custom foam inserts are more than a packaging accessory—they are your front-line defense against invisible, product-destroying static electricity. Whether you’re shipping microchips or storing circuit boards, the right foam insert not only protects your investment but also upholds your brand’s reputation for reliability.

Investing in custom ESD foam solutions today means fewer risks, happier clients, and a more sustainable workflow.