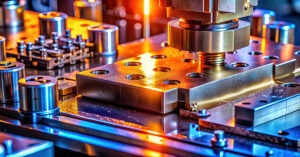

In the world of advanced manufacturing and fabrication, precision and efficiency go hand in hand. One process that perfectly embodies both is CNC tube bending — a highly accurate method used to shape metal tubes for countless industrial applications. From automotive exhaust systems to aerospace structures, tube bending has become an essential part of modern engineering.

What Is CNC Tube Bending?

CNC tube bending stands for Computer Numerical Control tube bending. It’s a process in which a computer-guided machine precisely bends metal tubes to specific angles and radii. The system uses pre-programmed instructions to control every movement, ensuring consistent, repeatable results every time.

Unlike manual bending, CNC technology eliminates human error and guarantees tight tolerances. This makes CNC tube bending services ideal for industries that demand high accuracy, durability, and visual perfection.

How the CNC Tube Bending Process Works

The process begins with a digital design or CAD model of the required tube shape. The CNC machine then interprets this design and controls mechanical components such as bending arms and clamps to form the tube exactly as specified.

Most tube bending services involve the following steps:

- Programming: Engineers input the design parameters into CNC software.

- Loading: The metal tube (steel, aluminum, copper, or titanium) is placed into the bending machine.

- Bending: The CNC system manipulates the tube to the desired shape using rotary draw or compression techniques.

- Inspection: Precision measuring tools verify the accuracy of bends before approval or assembly.

This level of automation ensures each bend is identical, even across thousands of units — a key factor in high-volume production.

Applications of Custom Tube Bending Services

The applications of custom tube bending services are nearly limitless. Industries rely on them for:

- Automotive: Fuel lines, roll cages, exhaust systems, and hydraulic lines.

- Aerospace: Lightweight tubing for aircraft structures and fluid systems.

- Architecture: Metal tubing for railings, frameworks, and artistic installations.

- Industrial Equipment: Tubular assemblies for machinery, conveyors, and heat exchangers.

- Furniture & Recreation: Curved metal frames for design and ergonomics.

With precision at the core, metal tube bending services allow manufacturers to create durable, complex, and visually clean structures.

Advantages of CNC Tube Bending

- Accuracy and Consistency – Each bend follows precise measurements with minimal variation.

- Design Flexibility – Allows complex geometries and multi-plane bending.

- Reduced Material Waste – Optimized programming ensures efficient material use.

- Faster Production – Automated systems complete projects quickly without sacrificing precision.

- Superior Aesthetic Quality – Smooth, uniform bends with no wrinkles or distortion.

For industries in need of both structural integrity and refined design, CNC tube bending services in Toronto and beyond offer an ideal balance between performance and appearance.

Tube Assembly Fabrication

In many applications, bending is only one part of the process. Tube assembly fabrication services go a step further by combining bent tubes into functional systems or frames. These assemblies often require cutting, welding, drilling, and fitting — all performed with the same level of precision as the initial bending.

Custom tubular assembly services ensure that every piece fits seamlessly into its larger structure, whether it’s an industrial frame, a vehicle chassis, or a mechanical component.

Quality Control in Tube Fabrication Services

Precision doesn’t end at bending. Every tube and assembly undergoes strict inspection and testing. Dimensional checks, pressure testing, and surface analysis confirm compliance with specifications.

A reliable provider of tube fabrication services uses state-of-the-art measuring systems to guarantee accuracy, consistency, and safety in every product delivered.

CNC Tube Bending in Modern Manufacturing

Today’s manufacturers rely on CNC tube bending service providers not just for production, but also for design collaboration. Engineers and clients work together to optimize designs for both performance and manufacturability. This partnership ensures that tubes are not only shaped correctly but also function efficiently within their systems.

Modern bending machines now integrate with CAD/CAM software, enabling digital prototyping, real-time adjustments, and reduced setup times. This advancement allows manufacturers to respond quickly to design changes and achieve mass customization — a growing trend in today’s industry.

Sustainability and Efficiency

Because custom tube bending services minimize waste and optimize material use, they also contribute to sustainability. By reducing scrap and energy consumption, CNC fabrication supports eco-friendly manufacturing practices without compromising quality.

Choosing the Right Partner for Tube Bending

When selecting a company for CNC tube bending or fabricated tube assemblies services, consider the following:

- Technical experience and skilled operators.

- Capability to handle various materials and diameters.

- Integration with CAD/CAM systems for design accuracy.

- In-house inspection and quality certification.

- Commitment to deadlines and communication.

Working with a partner who values precision and reliability ensures that your components meet the strictest engineering and safety standards.

Conclusion

As industries evolve, the demand for accurate, efficient, and flexible manufacturing continues to grow. CNC tube bending provides the foundation for creating complex shapes that drive modern innovation — from vehicles and buildings to machines and infrastructure.

Olympic Tool & Die Inc. has been a trusted name in custom manufacturing and precision engineering since 1976. With advanced equipment, skilled technicians, and a dedication to quality, the company delivers exceptional tube bending and assembly services across Ontario — ensuring every project meets the highest standards of performance and precision.