The aviation industry is known for its rigorous safety standards, complex supply chains, and emphasis on efficiency. However, in recent years, sustainability has emerged as an equally important priority. From reducing carbon emissions to adopting recyclable materials, airlines and aerospace manufacturers are rethinking every aspect of their operations, including packaging. In this context, Top Corrugated Box Manufacturers In Chennai are helping the aviation sector transition to eco-friendly packaging solutions that protect valuable components while minimizing environmental impact.

The Role of Packaging in Aviation Logistics

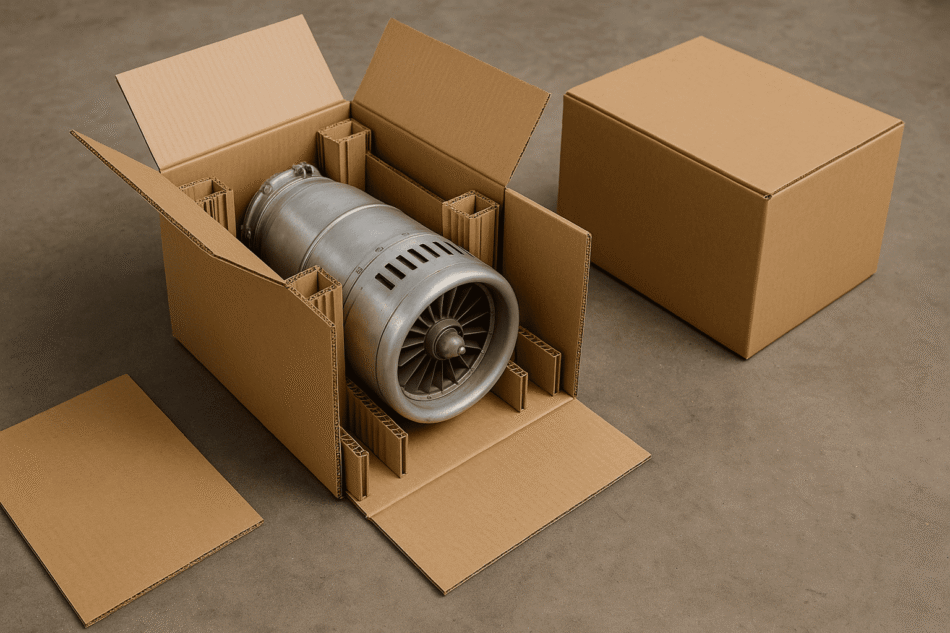

Aircraft parts—ranging from small electronic modules to large fuselage sections—are shipped across continents daily. These parts must arrive without damage, contamination, or delay. Packaging plays a critical role in this process, ensuring that components are secure, easy to handle, and compliant with both domestic and international shipping regulations.

Traditionally, many aviation parts were shipped in wooden crates or heavy-duty plastic containers. While durable, these options often involve higher environmental costs, including resource consumption and end-of-life waste. Corrugated packaging, on the other hand, offers a renewable, recyclable, and lightweight alternative that meets both performance and sustainability goals.

Why Eco-Friendly Corrugated Packaging Works for Aviation

-

Renewable Material Source

Most corrugated packaging is made from paper sourced from sustainably managed forests or recycled fibers. -

Recyclability

Used boxes can be recycled into new packaging, creating a closed-loop system that reduces waste. -

Lightweight Advantage

Reduced packaging weight lowers air freight fuel consumption, contributing to lower carbon emissions. -

Customizable Design

Corrugated packaging can be tailored to fit any aerospace component, reducing the need for excess filler materials. -

Strength with Sustainability

Multi-wall corrugated boards can handle heavy loads while remaining environmentally friendly.

Balancing Sustainability and Performance

One challenge in aviation packaging is ensuring that eco-friendly solutions do not compromise safety or performance. In many cases, corrugated packaging can match or exceed the durability of traditional materials, especially when designed with aerospace-specific requirements in mind.

Features like double- or triple-wall construction, moisture-resistant coatings, and reinforced edges make corrugated boxes capable of withstanding the rigors of global transport. In fact, many airlines and parts suppliers have successfully replaced heavier, less sustainable packaging with reinforced corrugated solutions without increasing damage rates.

Pairing Corrugated Packaging with Additional Materials

Corrugated boxes often form the main structure of aerospace packaging, but additional protective materials enhance their effectiveness. Midway in the supply chain, businesses frequently partner with Packaging Material Manufacturers In Chennai to source eco-friendly supplementary products such as biodegradable cushioning, recyclable bubble wrap alternatives, and compostable films. These materials not only protect against shocks, moisture, and dust but also ensure the entire packaging solution remains environmentally responsible.

By combining sustainable corrugated structures with equally sustainable protective materials, aerospace companies create packaging systems that align with both operational and environmental priorities.

Applications of Eco-Friendly Corrugated Packaging in Aviation

Eco-friendly corrugated packaging is now used in many areas of aviation logistics, including:

-

Avionics Systems – Sensitive electronics shipped in moisture-resistant corrugated boxes with anti-static liners.

-

Cabin Interiors – Seats, overhead bins, and panels packaged in custom-fit corrugated containers to prevent scratches.

-

Small Components and Fasteners – Organized in partitioned corrugated boxes for easy inventory management.

-

Maintenance, Repair, and Overhaul (MRO) – Spare parts shipped in reusable corrugated packaging to minimize waste.

-

Export of Large Parts – Triple-wall corrugated crates replace wooden alternatives, reducing weight and carbon footprint.

Compliance with Aviation and Environmental Standards

Aviation packaging must comply with strict safety and quality standards, such as AS9100 for aerospace quality management. Eco-friendly corrugated packaging can meet these requirements while also aligning with international sustainability goals, including ISO 14001 for environmental management.

In addition, certain export destinations require packaging to meet phytosanitary regulations. Corrugated packaging avoids the need for chemical fumigation treatments required for wooden crates, making it a safer and greener choice.

Case Study: Sustainable Transition by an Aircraft Parts Supplier

An aerospace parts supplier in South India was previously shipping components in wooden crates and rigid plastic containers. These provided durability but generated significant disposal challenges. After switching to moisture-resistant, triple-wall corrugated boxes with compostable internal cushioning, the company reduced packaging waste by 40% and shipping costs by 15% due to lower weight. Customers reported no increase in transit damage, validating the effectiveness of the new eco-friendly system.

Cost Considerations and Lifecycle Benefits

Eco-friendly corrugated packaging often costs less than heavy-duty alternatives, especially when considering total lifecycle value. Key cost advantages include:

-

Lower Freight Costs – Lightweight boxes reduce fuel charges in air freight.

-

Reduced Disposal Fees – Recyclable materials lower waste management expenses.

-

Reusability in Short-Term Logistics – Certain designs can be reused for multiple shipments.

-

Efficient Storage – Flat-packed corrugated boxes take up less warehouse space.

When factoring in reduced environmental impact and improved brand reputation, eco-friendly corrugated packaging offers both financial and operational benefits.

Sustainability Beyond the Box

Adopting eco-friendly packaging in aviation logistics also supports broader corporate sustainability goals. Airlines and aerospace manufacturers are under increasing pressure from regulators, investors, and passengers to demonstrate environmental responsibility. Packaging is a visible and measurable area where companies can make immediate improvements.

Many businesses are now incorporating life cycle assessments (LCAs) to evaluate the environmental footprint of their packaging choices, leading to more informed decisions and better long-term outcomes.

The Future of Eco-Friendly Corrugated Packaging in Aviation

As technology and materials science advance, the future of corrugated packaging in aviation will likely include:

-

Advanced Coatings – Bio-based coatings that improve moisture resistance without using harmful chemicals.

-

Smart Sensors – Embedded trackers to monitor environmental conditions in real time.

-

Increased Recycled Content – Higher percentages of post-consumer fiber in high-strength packaging.

-

Automation in Design – AI-assisted tools to optimize box dimensions for maximum efficiency and minimal waste.

These innovations will further improve the balance between sustainability, protection, and cost-effectiveness.

Best Practices for Aviation Companies Adopting Eco-Friendly Corrugated Packaging

-

Collaborate with Experts – Work with manufacturers who understand both aerospace and sustainability requirements.

-

Use the Right Board Grade – Match strength to part weight and fragility.

-

Incorporate Eco-Friendly Inserts – Replace plastic-based fillers with recyclable or compostable alternatives.

-

Train Logistics Staff – Ensure proper handling to extend packaging lifespan.

-

Monitor Results – Track damage rates, freight costs, and waste reduction after implementation.

Conclusion

Eco-friendly corrugated packaging is proving to be a game-changer in the aviation supply chain. It offers a sustainable, lightweight, and high-performance alternative to traditional shipping materials, ensuring that aircraft parts arrive safely while supporting environmental goals. With innovations in materials and design, and with strong partnerships between manufacturers and aerospace companies, corrugated packaging is set to become an even more vital part of aviation logistics in the years ahead.

By choosing eco-friendly solutions, the aviation industry not only protects its valuable cargo but also contributes to a cleaner, more sustainable future for global transportation.