Construction projects depend on accuracy. Every detail matters. A small mistake can cost time and money. That’s why layout planning is so important today. It guides the entire building process. It also helps teams stay organized from start to finish.

Across the USA, construction schedules get tighter every year. Teams want clear plans. They want better coordination. And they want fewer surprises on site. Professional construction layouts help them reach that goal. These tools turn complicated designs into simple, easy-to-follow steps.

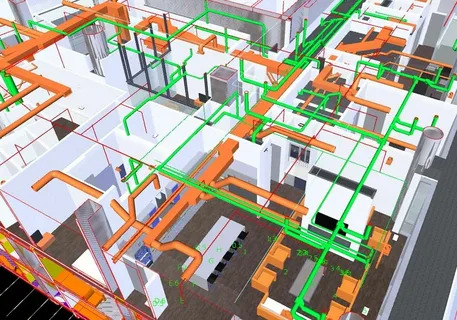

This is often where mep coordination drawing services becomes helpful for teams trying to learn more. Many builders also look for professionals with deeper experience. They want experts who understand layout techniques and advanced tools. That’s why services like standard cmu block sizes show up often in project discussions. These specialists help streamline the design process. They also minimize layout errors that can create long delays.

A strong layout plan creates confidence. Workers understand where everything goes. Managers can track progress better. And owners get a clearer picture of what their project will become.

Why Construction Layouts Matter So Much

If you’ve ever walked through a job site, you know how hectic it gets. People move fast. Materials arrive constantly. Machines run all day. Without a layout plan, things drift out of place. Walls shift. Slabs misalign. Equipment clashes. These mistakes create expensive fixes.

A professional layout keeps everyone on the same page. It reduces confusion. It helps maintain order even on a crowded site. And it gives every task a clear direction.

In the USA, codes and standards vary by state. A precise layout helps teams meet those standards with ease. It reduces risk. It prevents rework. And it supports better quality control for the entire build.

Turning Designs Into Real-World Measurements

A good layout doesn’t live only on paper. It must work in real space. That’s the challenge most teams face. Translating drawings into ground marks requires skill. It also requires good tools. And it definitely requires accuracy.

This is where advanced layout teams excel. They take digital plans and convert them into on-site measurements. They follow strict methods to ensure everything lines up. They also catch design issues early.

During this stage, many teams begin exploring solutions similar to mep coordination drawing services. Consultants help refine the layout. They check load paths. They study reinforcement plans. They verify every line, angle, and intersection.

These steps build trust throughout the project. No one wants to rebuild a wall twice. A good layout prevents that from happening.

Why Accurate Layouts Support Safer Projects

Safety matters more than anything. A poorly marked site creates risk. Workers may trip. Equipment may collide. And structures may become unstable if placed wrong. A clear and accurate layout organizes the entire site. It enhances visibility. It reduces stress. And it keeps the workflow smooth.

Many USA contractors rely on solid layouts because of increased safety expectations. Inspections move faster. Crews work more confidently. And tasks line up better across shifts.

Reinforcement Planning and On-Site Accuracy

Once structural planning begins, precision becomes even more important. Reinforcement placement depends on exact measurements. Steel bars must align properly. Concrete must pour evenly. Load distribution must match engineer expectations.

At this stage, builders often look into mep coordination drawing services as part of their planning. These services create detailed visual instructions. They show how reinforcement should be arranged. They also highlight potential clashes before installation begins.

Using these drawings reduces waste. It speeds up the reinforcement stage. And it prevents costly mistakes during concrete pours.

Professionals across the USA depend on these drawings to improve reliability. They help teams avoid last-minute changes that slow progress.

How Technology Makes Layouts Smarter

Construction technology keeps improving. Modern tools give layout teams huge advantages. Laser systems measure with incredible accuracy. Drones create fast site maps. And modeling software spots errors before crews reach the site.

These tools bring speed and clarity. They help teams build faster and smarter. And they help reduce the guesswork that often slows down construction.

Working with advanced tools also improves communication. When everyone sees the same model, confusion disappears. Teams make decisions faster. They also fix potential issues before they cause trouble.

Construction Market Depends on Precision

The construction market in the USA moves fast. Projects open quickly. Competition is high. Clients expect quick results and solid work. A project’s profitability often depends on keeping things efficient.

Accurate layouts help crews stay focused. They reduce rework. They support better scheduling. They also help meet local building codes without stress.

Because of these pressures, companies invest more in layout planning. It becomes a core part of their workflow. It builds a reputation for reliability. And it helps them win more bids.

Tips for Better Construction Layouts

Good layouts don’t have to be complicated. They just need structure. Here are some simple tips:

1. Start Early

Planning should begin long before crews arrive. Early layouts highlight conflicts quickly. They also make major decisions easier.

2. Keep Everything Updated

Designs change often. Make sure your layout updates too. Outdated marks create expensive errors.

3. Train Your Team

Crews should understand layout basics. Even a short briefing helps prevent mistakes on site.

4. Use Clear Markings

Make marks easy to see. Clear symbols prevent confusion in busy environments.

5. Work With Professionals

Specialists bring accuracy and experience. They solve problems before they reach the field.

These habits improve workflow. They also reduce stress when deadlines get tight.

Breaking Down the Layout Process

Construction layouts usually follow a few stages. Each stage matters. And each supports the next.

1. Site Scan or Review

Teams inspect the site. They check boundaries. They verify measurements.

2. Plan Conversion

Designs move from digital models into physical marks. Tools help translate the information accurately.

3. Marking and Verification

Crews place marks. Then they double-check them. This prevents misalignment.

4. Coordination

Layout teams coordinate with electricians, plumbers, and structural workers. This reduces conflicts.

5. Final Approvals

Managers check everything before building begins.

This process keeps projects clean and organized.

Using Layouts to Avoid Costly Mistakes

Small mistakes become big quickly. A misplaced wall affects plumbing. Misaligned columns disrupt roofing. Errors multiply fast.

Layouts catch these issues before construction starts. They highlight risks early. They simplify corrections. And they ensure every trade works on the same plan.

Accurate layouts also reduce material waste. Workers cut fewer pieces wrong. They measure correctly the first time. This saves money and prevents delays.

Why Layout Professionals Are Worth It

Hiring professionals brings peace of mind. They use better tools. They understand complex plans. And they work faster than untrained crews.

In the USA, professionals also understand regional building codes. They help projects meet inspection requirements. They also improve long-term durability through accurate placements.

Their experience makes everything easier. It helps teams stay focused. And it reduces stress on project managers.

Frequently Asked Questions

1. Why do construction layouts matter so much?

They help avoid errors, reduce waste, and support safer job sites.

2. When should layout planning begin?

It should start early in the design phase for best results.

3. How does strand engineering support layout accuracy?

It offers expertise that improves measurement precision and structural planning.

4. Why use rebar shop drawing services?

They create clear reinforcement maps that prevent installation errors.

5. Are modern tools necessary for layouts?

Yes. They improve accuracy and help teams work faster.