rotary dryers market innovations enhance sustainability, automation, and energy efficiency, driving industrial transformation through advanced technologies, hybrid systems, and data-driven intelligent drying solutions worldwide.

Introduction

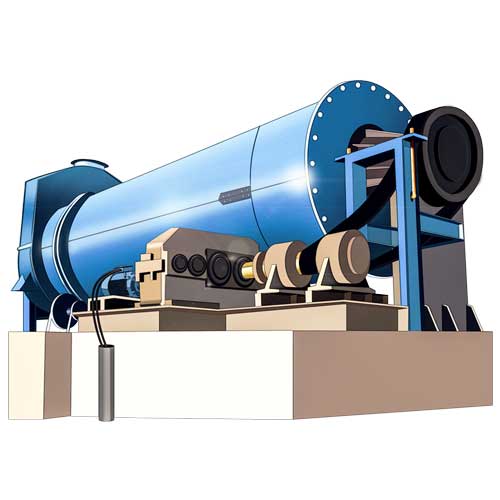

The rotary dryers market is experiencing an unprecedented wave of innovations that are reshaping the future of industrial drying systems. With the global focus shifting toward sustainable production, efficiency optimization, and digital integration, rotary dryers have evolved from simple heat-based machines into sophisticated, data-driven systems that maximize performance and minimize environmental impact. These innovations are revolutionizing industries such as mining, food processing, agriculture, chemicals, and energy, where drying operations form the backbone of production.

The rotary dryers market is no longer just about drying materials; it’s about engineering sustainability, precision, and intelligence into every process. Advanced control technologies, hybrid fuel systems, and eco-efficient designs are creating a new industrial paradigm—one where productivity and planet-friendly operations coexist harmoniously. As the demand for energy-efficient systems grows, the rotary dryers market stands at the forefront of industrial innovation, driving long-term transformation.

Technological Advancements Shaping the Modern Rotary Dryers Market

Over the past decade, the rotary dryers market has undergone a massive technological transformation. Modern dryers now feature integrated sensors, data analytics software, and automated control systems that ensure real-time precision in moisture removal and temperature regulation. These technologies have enabled industries to fine-tune processes, reduce waste, and optimize energy use like never before.

Digital monitoring systems are among the most influential innovations. By continuously tracking temperature, air velocity, and humidity levels, these systems allow operators to make instantaneous adjustments that improve consistency. Machine learning algorithms have also entered the rotary dryers market, allowing predictive control that anticipates process fluctuations and adjusts parameters automatically to maintain optimal performance.

This merging of automation and artificial intelligence is pushing industrial dryers toward smarter, more efficient, and fully autonomous operations.

Energy Optimization as a Central Innovation

Energy consumption has historically been one of the biggest challenges in industrial drying, making energy optimization a central focus of rotary dryers market innovations. New-generation rotary dryers are designed with heat recovery systems that recycle exhaust gases to preheat incoming air, reducing fuel requirements significantly. This not only lowers operational costs but also supports sustainability commitments.

Hybrid systems are another groundbreaking development. By combining renewable sources—such as solar, biomass, or biogas—with traditional fuels, hybrid rotary dryers ensure continuous operation while drastically cutting carbon emissions. Variable frequency drives (VFDs) and dynamic air control further fine-tune the energy balance, adapting to changing material loads in real time.

As industries increasingly pursue carbon-neutral goals, the rotary dryers market is becoming a cornerstone of global energy-efficient manufacturing.

Sustainable Engineering and Eco-Friendly Design

The sustainability movement has given rise to a new generation of environmentally conscious rotary dryers. Manufacturers are focusing on reducing carbon footprints by developing systems that emit fewer pollutants and utilize cleaner fuels. Advanced combustion systems, optimized airflow designs, and low-emission burners have become defining features of this evolution.

Moreover, the use of recyclable and corrosion-resistant materials in dryer construction ensures durability and reduces waste generation during maintenance. Many modern rotary dryers now incorporate life-cycle engineering principles that focus on longevity, resource efficiency, and reusability. These environmentally responsible designs have positioned the rotary dryers market as a key contributor to global sustainable industry goals.

Automation and Smart Control Systems Revolutionizing Operations

Automation has fundamentally transformed the rotary dryers market by enabling consistent, precise, and remote-controlled drying operations. The introduction of smart control panels and cloud-integrated monitoring systems allows operators to oversee entire production lines through digital dashboards.

These smart systems utilize data analytics to identify process inefficiencies, predict maintenance schedules, and prevent operational failures before they occur. As a result, companies can maintain continuous operation with minimal downtime. The implementation of real-time monitoring and automated fault detection not only enhances productivity but also ensures long-term operational safety and reliability.

Through these advancements, the rotary dryers market is redefining what it means to be both high-performing and intelligent in modern manufacturing.

Material Flexibility and Industry Diversification

Another defining innovation in the rotary dryers market is the ability to adapt to diverse materials and industries. Rotary dryers have evolved to handle varying material properties—such as particle size, moisture level, and thermal sensitivity—across sectors like fertilizers, chemicals, biomass, minerals, and food products.

Customized drying solutions now cater to specific industrial needs. For instance, indirect rotary dryers are being used in the food and pharmaceutical sectors to prevent contamination, while direct-fired dryers dominate in the mineral and cement industries where high temperatures are essential. This diversification underscores the rotary dryers market’s ability to remain relevant in multiple sectors, responding dynamically to shifting industrial requirements.

Digital Twin and Predictive Maintenance Revolution

One of the most exciting innovations shaping the rotary dryers market is the integration of digital twin technology. A digital twin creates a virtual replica of the physical dryer, allowing engineers to simulate and analyze operations in real time. This simulation helps in optimizing temperature distribution, airflow, and drum rotation before implementing changes in actual systems.

Predictive maintenance, supported by AI algorithms, further enhances reliability. By analyzing vibration patterns, temperature fluctuations, and energy consumption, predictive systems can forecast potential failures, allowing maintenance to occur before downtime happens. This predictive approach minimizes costs and extends the lifespan of rotary dryers, marking a new era of smart industrial maintenance.

Regional Innovation and Market Growth Patterns

Regional advancements are playing a crucial role in shaping the global rotary dryers market. North America and Europe lead in technological innovations such as automation, energy recovery, and advanced emission control. These regions prioritize eco-efficiency and digital integration, driven by strong environmental policies.

In contrast, the Asia-Pacific region is witnessing explosive growth in rotary dryers demand due to industrial expansion in countries like China, India, and Indonesia. Manufacturers here are adopting cost-effective, high-capacity systems that meet both economic and environmental objectives. Meanwhile, Africa and Latin America are increasingly turning to rotary dryers for agriculture, mining, and renewable energy processing, reflecting the market’s global versatility.

Innovation in Design Durability and Operational Longevity

rotary dryers market innovations now emphasize longevity and ease of maintenance. Modern dryers are constructed with advanced materials capable of withstanding extreme thermal stress and corrosive environments. Modular designs have simplified repairs, enabling faster component replacement and reduced downtime.

Additionally, manufacturers are introducing anti-corrosive coatings and improved lubrication systems that enhance performance reliability in challenging environments. These design innovations ensure that rotary dryers deliver long-term operational stability while minimizing maintenance costs, reinforcing their importance across industrial applications.

Challenges and Opportunities Driving Innovation

Despite rapid progress, the rotary dryers market faces challenges, including high initial setup costs and technical complexities in integrating digital systems. However, these obstacles are offset by long-term benefits such as reduced energy consumption, improved product uniformity, and lower lifecycle costs.

Furthermore, global emphasis on carbon reduction and sustainability is creating lucrative opportunities for innovation. Companies that invest in developing eco-smart rotary dryers are gaining a competitive advantage, as industries increasingly prefer energy-efficient systems that comply with environmental standards.

Future Outlook: The Next Generation of Rotary Dryers

The future of the rotary dryers market lies in convergence—where automation, renewable energy, and data intelligence intersect. The next wave of innovation will likely include AI-driven autonomous drying systems capable of self-calibration, hydrogen-based heating systems, and enhanced digital twin capabilities.

The use of nanotechnology and advanced material coatings will further improve thermal efficiency and reduce wear, extending dryer life. As industries continue to prioritize sustainability, these futuristic developments will redefine the role of rotary dryers as indispensable tools for industrial progress.

Conclusion

The rotary dryers market innovations signify a critical turning point in industrial evolution. From digital intelligence and automation to renewable energy and material versatility, every innovation is driving industries toward greater efficiency and sustainability. As environmental awareness and technological capabilities grow, the rotary dryers market is not only shaping the future of drying technology but also pioneering a smarter, cleaner, and more energy-efficient industrial era.