In boiler feedwater and process liquids, dissolved oxygen and carbon dioxide drive corrosion and reduce efficiency. Deaeration solves this by removing gases—often under vacuum. A Water Ring Vacuum Pump (also called a liquid ring vacuum pump) is a proven way to create and maintain that vacuum reliably, even when the gas stream is saturated with vapor or contains liquid carryover.

How a Liquid Ring Vacuum Pump Creates Vacuum

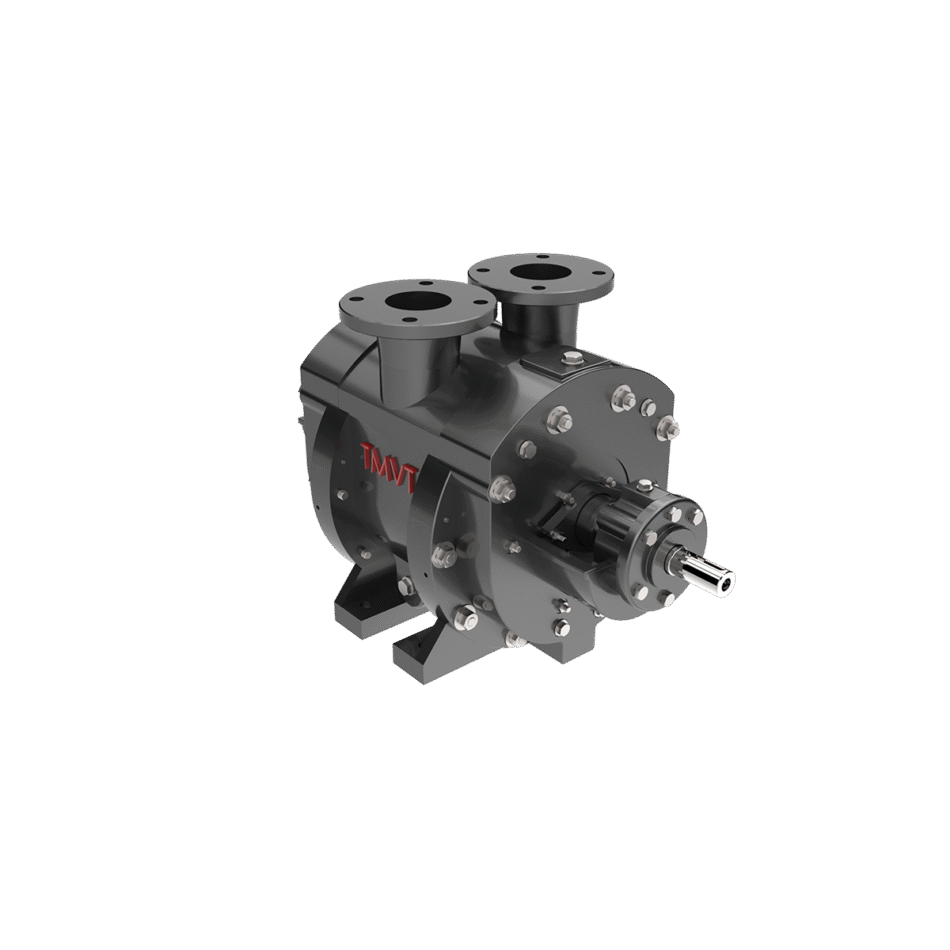

A liquid ring vacuum pump has an impeller mounted eccentrically inside a cylindrical casing. The casing is partially filled with sealing liquid (commonly water). When the impeller rotates, centrifugal force throws the liquid outward to form a rotating “ring” along the inner wall. Because the impeller is offset, the spaces between its blades and the liquid ring expand and contract once per revolution:

- Suction phase: As a cell passes the inlet port, the liquid ring pulls back from the impeller hub and the cell volume increases, drawing in gas/vapor from the process.

- Compression phase: Continuing rotation forces the liquid ring inward, shrinking the cell volume and compressing the trapped gas.

- Discharge phase: The compressed gas exits through the discharge port, along with a small amount of sealing liquid.

This simple geometry yields a continuous, pulsation-free vacuum. Crucially, the sealing liquid absorbs heat of compression and condenses part of the vapor load, boosting effective capacity and stability—ideal for wet, saturated streams common in deaeration duties.

Why Vacuum Improves Deaeration

Deaeration efficiency depends on mass transfer between liquid and gas phases. Pulling a vacuum lowers the partial pressure of dissolved gases and the boiling point of the liquid, which:

- Accelerates gas release: Oxygen and CO₂ leave the water faster when their partial pressures drop.

- Enhances flashing/stripping: At reduced pressure, a portion of the water flashes to vapor, sweeping out dissolved gases.

- Enables lower-temperature operation: Plants can achieve the same degassing at gentler temperatures, protecting heat-sensitive streams.

Liquid ring pumps maintain a steady vacuum level across varying loads, preventing the pressure oscillations that would otherwise disrupt stripping efficiency.

Key Advantages in Deaeration Service

- Handles vapor and slugs of liquid: The pump’s working fluid is already a liquid ring, so occasional carryover doesn’t damage internals—unlike dry pumps.

- Thermal damping: Sealing liquid absorbs compression heat, stabilizing performance during transients (startup, turndown, and feed swings).

- Corrosion-resistant options: Materials and seal liquids can be selected for aggressive media; stainless steel options are common in water treatment and chemical duty.

- Quiet, low-vibration operation: The rotating liquid ring provides smooth compression with minimal pulsation.

Operating Factors That Matter

- Seal liquid temperature: Colder sealing liquid improves attainable vacuum because it condenses more vapor and reduces back-pressure. Warm seal liquid raises saturation pressure and limits ultimate vacuum. Consider seal-liquid coolers or partial recirculation loops.

- Service fluid management: Choose once-through or recirculated sealing systems based on water availability, contamination risk, and heat balance. Add separators to recover and reuse liquid, and strainers to protect the pump.

- Anti-cavitation protection: At deep vacuum and high temperatures, install vacuum relief or anti-cavitation valves to protect internals and stabilize operation.

- Right-sizing for duty: Match volumetric capacity to worst-case gas load (including flash vapor), not just steady-state oxygen/CO₂ release. Review NPSH-like inlet conditions (available pressure and temperature) to prevent choking.

- Controls and VFDs: Variable-speed control helps hold a tight vacuum setpoint while trimming energy use during turndown.

Typical Deaeration Setups

In water treatment and boiler makeup, the vacuum deaerator often includes a spray or tray section to maximize liquid–gas contact, with the liquid ring pump maintaining sub-atmospheric pressure in the vessel. A demister and knock-out pot protect the pump from excessive entrainment. Discharged gas/liquid passes to a separator, sending gas to vent and returning sealing liquid to drain or a cooler/recirculation tank.

Conclusion

Liquid ring technology is inherently suited to deaeration because it tolerates wet, saturated streams while delivering steady vacuum and thermal stability. By managing seal-liquid temperature, sizing for vapor peaks, and integrating simple safeguards, plants achieve fast oxygen/CO₂ removal, longer asset life, and consistent boiler or process performance day in, day out.