Digital twins are no longer futuristic concepts. They are now integral to next-generation IoT dashboard development services. In 2025, over 70% of asset-intensive organizations will deploy digital twins, up from 13% in 2021 (Gartner). Furthermore, the global digital twin market is expected to grow from $17.7 billion in 2023 to $137 billion by 2030 (Grand View Research).

With this surge, the need for advanced, interactive, and insightful IoT dashboards has grown. Businesses now seek IoT Dashboard Development Services that integrate digital twin capabilities to enhance decision-making, monitoring, and real-time asset visualization.

What Is a Digital Twin?

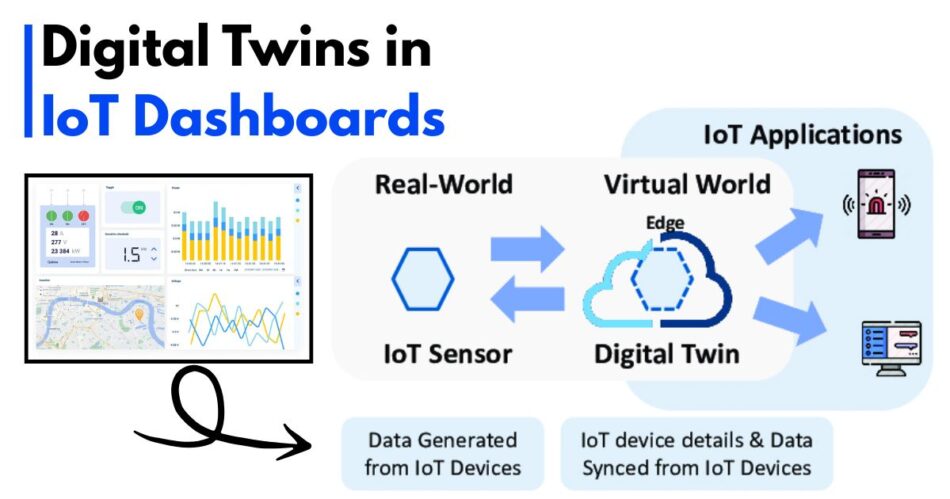

A digital twin is a virtual replica of a physical object, process, or system. It uses real-time data from sensors and IoT devices to mirror physical states and behaviors in a digital environment. This helps teams analyze, simulate, and predict performance without affecting the real-world asset.

How Digital Twins Enhance IoT Dashboards

1. Real-Time Visibility

Digital twins offer:

- Real-time status monitoring

- Visualization of operational parameters (temperature, pressure, speed, etc.)

- Alerts and anomalies based on sensor input

Example:

A digital twin of a wind turbine can display real-time blade RPM, vibration levels, and maintenance status on an IoT dashboard. This allows engineers to react before a fault occurs.

2. Predictive Analytics & Simulation

With machine learning and historical data, digital twins support:

- Performance simulations under varying conditions

- Predictive maintenance recommendations

- Failure risk estimation

Example:

In manufacturing, a digital twin can simulate the impact of machine wear over time. Engineers can visualize this on the IoT dashboard and adjust operations accordingly.

3. Operational Efficiency

Though we avoid vague terms like “streamline,” digital twins enable:

- Optimization of supply chains by simulating disruptions

- Better resource allocation using real-time data

- Faster response time through intelligent alerts

Architecture of an IoT Dashboard Powered by Digital Twins

| Layer | Description |

| Physical Layer | Machines, sensors, devices generating real-world data |

| Data Collection | IoT gateways and APIs pushing real-time data to the cloud |

| Twin Modeling | Algorithms create a virtual replica using data and operational logic |

| Dashboard Layer | User interface displaying metrics, simulations, predictions, and alerts |

IoT Dashboard Development Services must build a seamless integration of these layers for system reliability and ease of monitoring.

Use Cases Across Industries

1. Manufacturing

- Monitoring production lines

- Simulating downtime and optimizing shift schedules

- Visualizing machine health and maintenance needs

2. Smart Cities

- Digital twins of utility grids for energy balancing

- Traffic flow predictions using road infrastructure twins

- Water system leak detection via pipeline twins

3. Healthcare

- Simulating patient vitals and treatment responses

- Predicting medical equipment wear

- Displaying ICU load and resource allocation on dashboards

4. Logistics and Warehousing

- Real-time visualization of warehouse operations

- Vehicle tracking through digital twins of delivery fleets

- Predictive path optimization and bottleneck resolution

Key Components Required for Digital Twin-Enabled IoT Dashboards

● Data Integration

- Sensor and telemetry data ingestion

- Cloud and edge synchronization

- Time-series databases

● Visualization Tools

- 2D and 3D models of assets

- KPI widgets and performance gauges

- Color-coded alerts and heatmaps

● Simulation Engines

- AI/ML models for behavior prediction

- What-if scenario analysis modules

- Real-time physics-based simulators

● Security Protocols

- End-to-end encryption of data streams

- Role-based dashboard access

- Compliance with industry standards (e.g., ISO, HIPAA)

Benefits of Merging Digital Twins with IoT Dashboard Development Services

| Benefit | Description |

| Reduced Downtime | Predictive alerts before critical failures |

| Enhanced Decision-Making | Live data with historical trends for context |

| Accurate Planning | Simulation of load, wear, and lifecycle usage |

| Remote Monitoring | Control room access to geographically dispersed systems |

| Cross-Departmental Insights | Engineers, managers, and analysts get a unified, actionable interface |

Challenges in Implementation

● High Initial Setup Costs

Creating accurate 3D or system-level twins involves intensive modeling and data validation.

● Data Quality & Integration

Poor-quality sensor data can lead to incorrect simulations or misleading dashboard visuals.

● Scalability

Maintaining performance when scaling to hundreds or thousands of twins demands robust backend architecture.

Real-World Example: Siemens & Digital Twins

Siemens uses digital twins for its gas turbines. Each unit’s twin simulates:

- Temperature dynamics

- Fuel efficiency

- Rotor blade wear

IoT dashboards display this data in real-time, helping field teams predict and avoid outages. The result? Up to 30% maintenance cost reduction and 25% efficiency improvement.

Best Practices for Developing Digital Twin-Based IoT Dashboards

● Modular Design

- Design reusable dashboard components for temperature, pressure, and load

- Build APIs to plug in various twin models

● Real-Time Sync with Edge Devices

- Enable edge computing for faster feedback

- Sync twin states even with intermittent connectivity

● Adaptive User Interfaces

- Allow role-based views: engineer, operator, analyst

- Use drag-and-drop widgets for dashboard customization

● Regular Model Updates

- Periodically re-train simulation models using new data

- Validate twin accuracy through physical inspections

Future Outlook: Digital Twins + Generative AI

In 2025 and beyond, digital twins will converge with generative AI. This will enable:

- Autonomously updating dashboards based on twin insights

- NLP-based command inputs (“Show compressor wear pattern for past 3 months”)

- Auto-simulation of downtime scenarios and real-time visual replay

This shift demands that IoT Dashboard Development Services evolve from static visualizations to interactive, simulation-driven intelligence platforms

Conclusion

Digital twins are shaping the next era of real-time, intelligent, and simulation-driven dashboards. When integrated with IoT Dashboard Development Services, they provide unmatched value through predictive insights, real-time monitoring, and system-level transparency.

From manufacturing to healthcare, the use of digital twins in dashboards is not just innovative—it’s now essential. For companies aiming to enhance operational decision-making and asset management, digital twin-enabled dashboards offer a clear path forward.

Frequently Asked Questions (FAQs)

1. What is the difference between a digital twin and a traditional simulation model?

A digital twin is a real-time, continuously updated virtual replica of a physical asset, powered by live sensor data. In contrast, traditional simulation models are static and rely on preset scenarios or historical data, lacking real-time responsiveness or bidirectional communication with physical systems.

2. How do digital twins improve the effectiveness of IoT dashboards?

Digital twins enhance IoT dashboards by enabling real-time asset tracking, predictive simulations, and interactive 3D visualizations. They help users monitor equipment behavior, simulate future scenarios, and detect anomalies, all from a centralized, data-rich dashboard interface.

3. Are digital twins suitable for small-scale IoT applications or only for enterprise-level systems?

While digital twins are often used in large enterprises, they are increasingly scalable and cost-effective for small-scale IoT implementations. With advances in cloud computing and edge AI, even small manufacturers and facilities can now adopt digital twins for targeted use cases like machine health monitoring or energy optimization.

4. What types of data are essential to building an effective digital twin for IoT dashboards?

Essential data includes:

- Sensor data (e.g., temperature, vibration, pressure)

- Machine telemetry

- Operational logs

- Historical performance data

- Configuration and engineering specs

Accurate and high-quality data ensures the digital twin accurately mirrors real-world conditions and provides actionable insights on the IoT dashboard.

5. What are the biggest challenges in integrating digital twins with IoT dashboard development services?

Major challenges include:

- Data integration complexity from heterogeneous devices

- Ensuring real-time synchronization between physical and digital assets

- High initial modeling costs

- Cybersecurity risks if data pipelines are not secured

- Scalability concerns in large deployments

Partnering with experienced providers of IoT Dashboard Development Services can help overcome these obstacles with tested architectures and tools.