One of the most significant factors that contributes to smooth operations at the warehouse is effective packaging. When teams are occupied too long finding pallets or locating tools, productivity declines and delays accumulate. That is why a lot of warehouses have turned to the , a sistrapping kitsmple, one-size-fits-all solution that will help to maintain the pace constant and unchanged.

Streamlined Tools That Speed Up Work

One of the most significant benefits of strapping kits is the ease they add to the packing work. All the tools required to secure a pallet, such as straining rolls, tensioners, sealers, and seals, are packed into a single organised set. Employees do not spend time searching for and locating lost tools or attempting to fit various pieces together. Instead, they just grab the kit and begin strapping it, and it keeps things running smoothly even at peak times.

Mobility That Saves Minutes

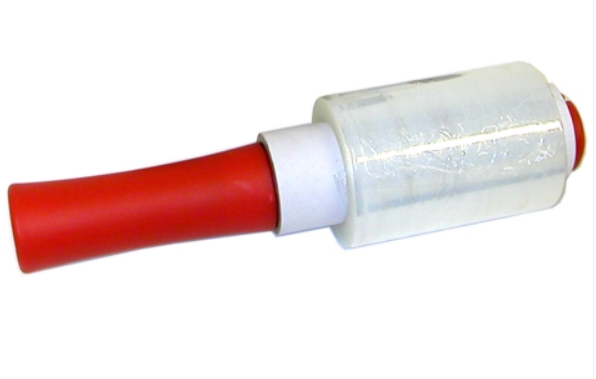

The reason why many warehouses use a pallet banding kit is that it will frequently be accompanied by portable dispensers or trollies. This mobility gives workers the opportunity to take the tools to the pallet rather than to move pallets within the warehouse. Walking time, repositioning, and unnecessary movement are reduced, resulting in clearly faster pallet preparation.

Safe Loads With Less Rework

A properly strapped pallet not only keeps things bound together but also keeps the supply chain flowing. Strapping kits help to maintain the appropriate tension and achieve the sealing process, minimising the possibility of unstable and falling loads during transportation. Warehouses prevent rework, loss, and wastage of products during the resettling of damaged goods by maintaining tight pallets and keeping them secure the first time.

Simple to Learn, Easy to Use

The experience of warehouse teams varies, and this is where a simple and predictable system is essential. Since every part of a strapping kit fits, employees can acquire the procedure in a short time and do it regularly. Regardless of whether polypropylene, polyester or steel will be used as a lighter or heavier material, the kit allows the workers to accomplish their tasks with confidence and reduced experimentation.

Reduced Costs Due to Increased Efficiency

An entire strapping kit saves wastage, incompatible tools and strap breakages. This not only makes the process faster but also enables control over the packaging costs. Having trustworthy tools and synchronised materials, warehouses will produce more output with fewer efforts and costs.

Conclusion

Strapping kits have become very important to warehouses that want to operate at a faster, smarter and with fewer interruptions. They make daily operations efficient through increasing the rate of packaging, as well as improving the stability of the loads. To the businesses that seek to have reliable and ready-to-use solutions, The Pallet Wrap Store provides quality strapping kits that assist warehouses to having a smooth and productive working process.