The packaging is important in the determination of the customer perception and product safety. Companies using custom heat seal paper that runs through heat sealing should understand the value of layouts when it comes to ensuring uniformity of quality. The setups of various things, including the designs, the seals, as well as the structural features, are dictated by the layouts. A shoddy layout makes materials get wasted, and the design gets distorted, as well as causing certain functional problems. Through strategic placement and planning, businesses can improve their branding and usability. The layouts offer the pattern to facilitate long-life and aesthetic values. Firms that have acquired the mastery of layout optimization end up enjoying this efficiency and reliability. Punchy layouts make packaging a super branding tool.

Layout Importance

Packaging depends on a clever configuration design that augments functionality and look. The arrangement, in case of custom heat seal paper, has to be a mix between usability and branding. A bad layout may involve loss of material, lack of clarity, or areas where sealing is not uniform. Streamlined packaging layouts make it easy to use the pack at the same time as making it easy to stand out. Companies that pay attention to proper layouts have more success on both the protective and presenting fronts. Careful attention to detail is incorporated so that every fold, cut, and print position functions. The significance of Layout is that it saves time, saves money, and increases functionality.

Design Balance

Effective layouts are based on the balance of branding and structure. Designs on custom seal paper should take into consideration the seal zones, print alignment, and cutting lines. There is a controlled overall design to make the text and logos legible after pressing or folding. The superimposition of critical images with seal lines leads to deformed images, whereas inferior margins lead to low durability. Package designers must come up with mock-ups before concluding layouts. Trial combinations of design placements avert errors in mass production. Financial stability of technical requirements of sealing, and brand image lead to enhanced consumer appeal. Efficient and long-term success is the result of professional planning of layouts.

Printing Focus

The focus of the layout optimization of packaging is printing. It is important to position logos, slogans, and imagery on custom printed heat seal paper. Placement should not create any seam interference, and there should be clarity on all the packages. Out-of-alignment printing dulls the effect of brand promotion and can yield uneven results. Design elements that printing strategies should incorporate include the selection of the proper ink coverage and high-definition designs. Bleed areas also need to be taken into account in the layouts to eliminate undesirable cutoffs. Correct printing print focus gives an exuding polish to show brand professionalism. Aligning well, the placement of print conveys quality and creates better trust with the customers.

Bag Formation

There is a difference in the layout when coming up with packaging types, particularly in the production of heat seal paper bags. A bag involves folding, closing, and cutting, and all of them influence layout planning. Designers would have to address space reservations to seams, gussets, and handles where necessary. Placing graphics or text out of position can completely spoil the appearance of the bag. Good layouts combine the needs of structure with nice fun. Testing prototypes will enable businesses to determine the durability and appearance. A well-designed bag layout will have a strong bag frame, and it can make the packaging functional and aesthetically attractive. Accuracy at this phase translates into wastage that is minimized and use that is more robust.

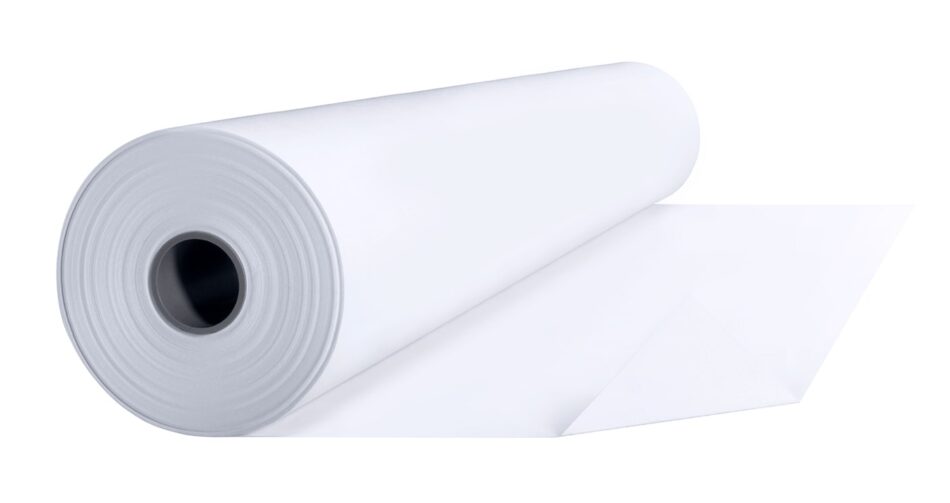

Roll Efficiency

Large-scale production by packaging businesses usually depends on a heat seal paper roll. The rolls need to be smartly spaced due to optimization of layout requirements. Unity in the roll means uniform packaging. Rolls also require designs that are continuous and do not experience misalignment during any processing. Efficient layouts make maximum usage of paper and minimal wastage of paper. Automation produces business benefits as the rolls are optimised with an appropriate design flow. Minimal waste and concision are elementary to lasting achievement. Roll efficiency predetermines the speed of production and cost-effectiveness in the approach to packaging.

Sheet Planning

Flat packaging needs an exclusive method compared to the rolls. The layouts that use heat seal paper sheets require optimum space utilization as well as clear design. Sheets can be more accommodating, but will significantly need planning in order to avoid overlap. Designers have to take into account margins, cut guides, and sealing edges. Streamlined designs make sure that logos do not get lost in folds. Sheets are also positively affected by straightening for better processing. Trial runs on sample sheets can provide information to a great extent prior to mass printing. With the help of sheet planning, a brand is able to stay precise and consistent throughout its packaging units.

Wholesale Strategy

Non-standard packaging requires layouts that accommodate large orders. Companies employing heat seal paper wholesale should be concerned with scalability and similarity. Mass production involves layouts that allow repetition and efficient use and minimise design errors. Improper planning at this level may cause a lot of material waste. The streamlined designs are such that the packaging of all orders contains consistent branding, even when the orders in question consist of thousands of packages. Another strategy that should be considered at the wholesale level entails the planning of variety in terms of the shape and sizes of products. Quality on borders maintains customer confidence. The optimization of the layout of wholesale ensures long-term stability and performance of custom food basket liners and brand image.

Conclusion

Minimizing the layout of custom heat seal paper involves more than just beauty. It entails technical exactness, tactical plan placement, and productivity in all production formats. The layout optimization is backed by every step of the process that helps it to be durable, clear, and have a brand impact. Ineffective layouts may involve wastage, destruction, and poor branding, whereas effective layouts increase performance. Designs of rolls, sheets, and bags are tested, planned and adjusted in order to achieve success. Companies that perfect designs command a good packaging identity in the market. Stable and well-organized, optimized layouts make packaging another stable brand asset.