The wrong choice of PCB assembly partner can ruin your whole project. With delayed timelines, quality problems, and unforeseen expenses, a poor choice impacts everything from your product launch to your bottom line.

The printed circuit board assembly marketplace is filled with choices, but not all of them are created equal. Not all vendors provide the same degree of expertise, reliability, or service. Some are specialists at high-volume production but bog down with prototypes. Others guarantee fast turnaround but produce low-quality products.

- Assess Their Technical Capability and Gear

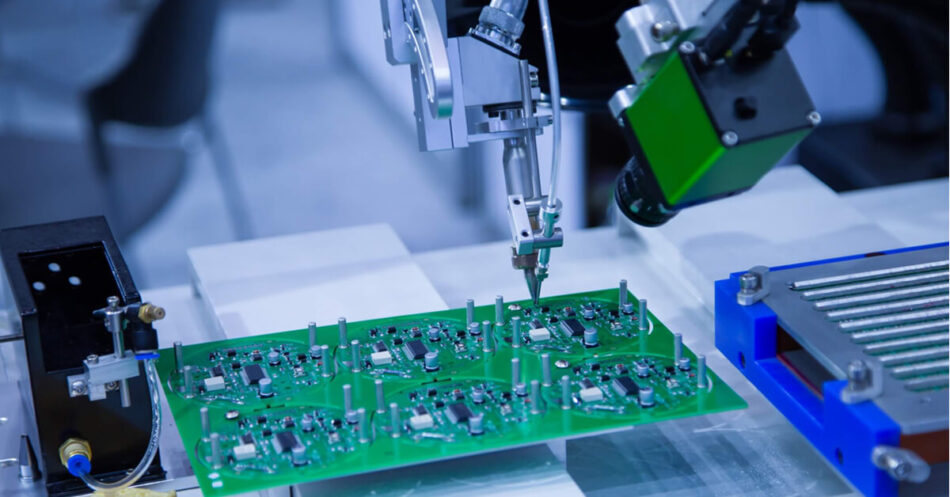

Your PCB assembly vendor’s technical ability is the cornerstone of your project’s success. Begin by reviewing their gear and manufacturing process.

Surface Mount Technology (SMT) Capabilities

Surface mount components are utilized widely in modern electronics. Ensure that your prospective partner possesses current SMT equipment with the ability to accommodate your particular component sizes. If your design contains fine-pitch components such as 0201 resistors or ball grid arrays (BGAs), ensure they possess the precision placement machines and inspection tools required.

Inquire about their component size restriction and placement tolerance. A good assembly house will have specific information on hand regarding equipment capability.

Through-Hole Assembly Services

Although SMT prevails in today’s PCB assembly, most designs still find a need for through-hole components. Make sure your partner does both automated and manual through-hole assembly services. Wave solder capability is especially desirable for high-volume production runs.

Inspection and Testing Equipment

Quality control distinguishes professional assembly services from hobbyist operations. Seek out partners that are armed with:

- Automated Optical Inspection (AOI) systems

- In-circuit testing (ICT) capabilities

- Hardware testing equipment

- X-ray inspection for internal solder joints

Design for Manufacturing (DFM) Support

The best PCB assembly partners don’t simply assemble your boards—they optimize your design for manufacturing. That means they identify potential issues in assembly before production and recommend changes to save costs or enhance reliability.

- Evaluate Quality Standards and Certifications

PCB assembly quality affects your product’s reliability and your firm’s reputation. Reputable assembly partners have a high quality standard supported by industry certifications.

ISO Certifications

ISO 9001 certification shows a dedication to quality management systems. For electronics production, use ISO 13485 (medical devices) or AS9100 (aviation) if your products target these markets.

IPC Standards Compliance

The Association Connecting Electronics Industries (IPC) dictates the standards for PCB assembly. Your partner must meet:

- IPC-A-610: Acceptability of Electronic Assemblies

- IPC/WHMA-A-620: Requirements for Cable and Wire Harness Assemblies

- IPC-J-STD-001: Requirements for Soldered Electrical and Electronic Assemblies

Environmental and Safety Certifications

Sustainable manufacturers hold certifications such as RoHS compliance for lead-free manufacturing and ISO 14001 for environmental management systems.

Quality Control Processes

Aside from certifications, learn their real quality control procedures. How do they inspect incoming components? What are their testing protocols? How do they monitor and respond to quality problems?

See samples of their quality documents and inquire about their defect rates. Openness in quality measures signals a partner devoted to ongoing improvement.

- Look into Production Volume and Scalability

Your production needs right now are important, but so are your future expansion plans. Your ideal PCB assembly partner must fit both your short-term needs and future growth ambitions.

Prototype and Low-Volume Production

If you’re creating new products, prototype assembly capability is important. Seek partners with the ability to produce small quantities without minimum order quantities that drain your budget.

Quick turnaround on prototypes keeps your development cycle moving quickly. Some assembly houses have expedited options for quick prototype requirements.

High-Volume Manufacturing

For production products, review their high-volume manufacturing capacity. This involves:

- Capacity of the available production lines

- Computer-controlled assembly processes

- Inventory control systems

- Supply chain contacts

Flexible Manufacturing Services

The ideal partners provide flexibility for varying volumes of production. They must offer competitive pricing on small runs as well as large runs, with the ability to ramp up or down production according to demand.

- Geographic Considerations

Think about where your assembly partner is located. Local partners provide benefits such as ease of communication, reduced shipping time, and easier control. But offshore partners may be cost-advantageous for mass production.

Analyze Communication and Customer Service

Technical capabilities mean little without effective communication. Your PCB assembly partner should be responsive, proactive, and easy to work with throughout your project.

Project Management Support

Professional assembly partners assign dedicated project managers who serve as your primary point of contact. They should provide regular updates, manage timelines, and coordinate between different departments.

Technical Support Team

Access to skilled engineers and technicians ensures issues are settled promptly. Your partner must provide technical support both in the quoting stage and in production.

Communication Channels and Response Times

Assess how they prefer to communicate and respond. Are you able to contact them readily by phone, email, or online communication? How long do they take to reply to questions?

Documentation and Reporting

Meticulous documentation avoids misunderstandings and ensures project success. Your partner must provide:

- Complete quotes with specifications

- Assembly documentation and drawings

- Quality certificates and production reports

- Shipping details and tracking

Problem Resolution Process

There are sometimes issues with production. Inquire about their problem resolution process. How do they deal with quality problems? What is their policy for handling delays or defects?

- Assess Pricing Structure and Value

Cost is always a factor, but the lowest price option never necessarily offers the best value. Be more interested in understanding the overall cost of ownership than in the initial price.

Clear Pricing Models

Responsible assembly partners give detailed, transparent quotes that outline all fees. These include:

- PCB fabrication fees (if applicable)

- Component purchasing fees

- Labor costs for assembly

- Measurement and inspection fees

- Handling and shipping fees

Hidden Fees to Avoid

Beware of partners giving unclear quotes or appending surprise fees down the line. Typical hidden fees are:

- New product setup fees

- Engineering change order (ECO) fees

- Expedite fees for urgent orders

- Minimum order volumes that are not compatible with your requirements

Value-Added Services

Look at the whole package of services provided. Partners who deliver more value by way of services such as:

- Component purchasing and procurement

- Inventory management

- Drop-shipping to your customers

- Warranty extension beyond the original period

These services could offset higher assembly costs by cutting your internal overhead.

Payment Terms and Flexibility

Assess payment terms and flexibility. Some partners provide net payment terms for repeat customers, whereas others expect payments before delivery. Note how their payment conditions correspond with your needs for cash flow.

Conclusion

Selecting the proper PCB assembly partner involves striking a balance between several variables. Develop a scoring system that assigns weights to each category according to your particular requirements. A prototyping startup may prioritize fast turnarounds and minimal minimum orders, whereas a mature firm may value high-volume capacity and cost savings.

Request quotes from multiple partners and compare not just pricing, but their overall approach to your project. The best partners ask detailed questions about your requirements and offer suggestions to improve your design or reduce costs.

Don’t hesitate to ask for references from current customers, especially those with similar project requirements. A reputable assembly partner will gladly provide references and case studies demonstrating their capabilities.