In today’s fast-moving world of engineering and design, materials that are both lightweight and durable are in high demand. One such innovation making a big impact is Prepreg Composites. From aerospace to automotive, sports equipment to wind energy, these advanced materials are reshaping how products are designed and built.

What Are Prepreg Composites?

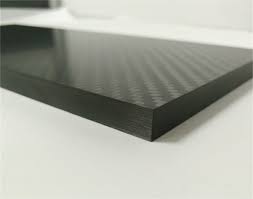

The term “prepreg” refers to reinforcement fibers—like carbon fiber, fiberglass, or aramid—that have been pre-impregnated with a specially formulated resin. This resin is partially cured, so the material is ready for use but still flexible enough to be shaped. By using Prepreg Composites, manufacturers save time while ensuring consistent quality and strength in the final product.

Why They Are Popular

The biggest reason industries prefer Prepreg Composites is their combination of lightweight performance and strength. Unlike traditional materials like steel or aluminum, prepregs deliver exceptional stiffness without adding bulk. They also offer excellent fatigue resistance and can withstand extreme temperatures—making them ideal for demanding applications such as aircraft wings, race car parts, or even medical devices.

Another advantage is precision. Because the resin content is pre-controlled, the risk of human error during production is minimized. This leads to highly reliable components that meet strict industry standards.

Applications Across Industries

- Aerospace: Prepreg composites are used in aircraft fuselages, interior panels, and even spacecraft structures, reducing weight and increasing fuel efficiency.

- Automotive: High-performance cars rely on prepregs for body panels, spoilers, and structural parts to enhance speed and safety.

- Sports equipment: From tennis rackets to bicycles, prepreg composites improve performance by making gear lighter and more durable.

- Renewable energy: Wind turbine blades made from prepregs are stronger and longer-lasting, helping generate clean power efficiently.

Final Thoughts

From airplanes to bicycles, Prepreg Composites are changing the way products are built and used. They provide the strength of traditional materials without the added weight, making them an essential part of modern engineering. As technology continues to evolve, we can expect prepregs to play an even bigger role in shaping industries worldwide.