In industrial and commercial ventilation systems, selecting the right fan technology is critical to achieving optimal airflow, efficiency, and reliability. Among the different types of fans available, centrifugal fans stand out as the preferred choice when applications demand high static pressure. Whether in HVAC systems, industrial dust collection, material handling, combustion air delivery, or cleanroom environments, centrifugal fans consistently offer the performance characteristics needed to overcome intense resistance within a duct or process system.

Understanding why centrifugal fans excel in these situations requires examining their operating principles, mechanical design advantages, and performance behavior under load. This article explores the reasons engineers choose centrifugal fans for high-static-pressure needs and highlights key considerations when specifying them for demanding applications.

Understanding Static Pressure and Its Importance in Fan Selection

Static pressure refers to the resistance encountered by airflow as it moves through a system. This resistance may come from duct length, filters, dampers, bends, obstructions, diffusers, or process equipment. In environments where airflow must pass through dense materials, long duct runs, or tightly packed components, static pressure can be substantial.

Fans are selected not just for volume (CFM or m³/hr) but also for their ability to maintain airflow against this resistance. Centrifugal fans generate significantly higher static pressure compared to axial fans because of their air-handling mechanism, making them the logical choice when performance must be maintained under challenging conditions.

NOTE:- Industries had consistently chosen Centrifugal fans in UAE for their proven ability to manage ventilation challenges in harsh conditions. Their rugged build and stable airflow had made them a preferred solution across factories, warehouses, and commercial settings. To secure high-quality systems, you were advised to consult Airody Trading LLC for reliable procurement.

How Centrifugal Fans Work and Why Their Design Supports High Pressure

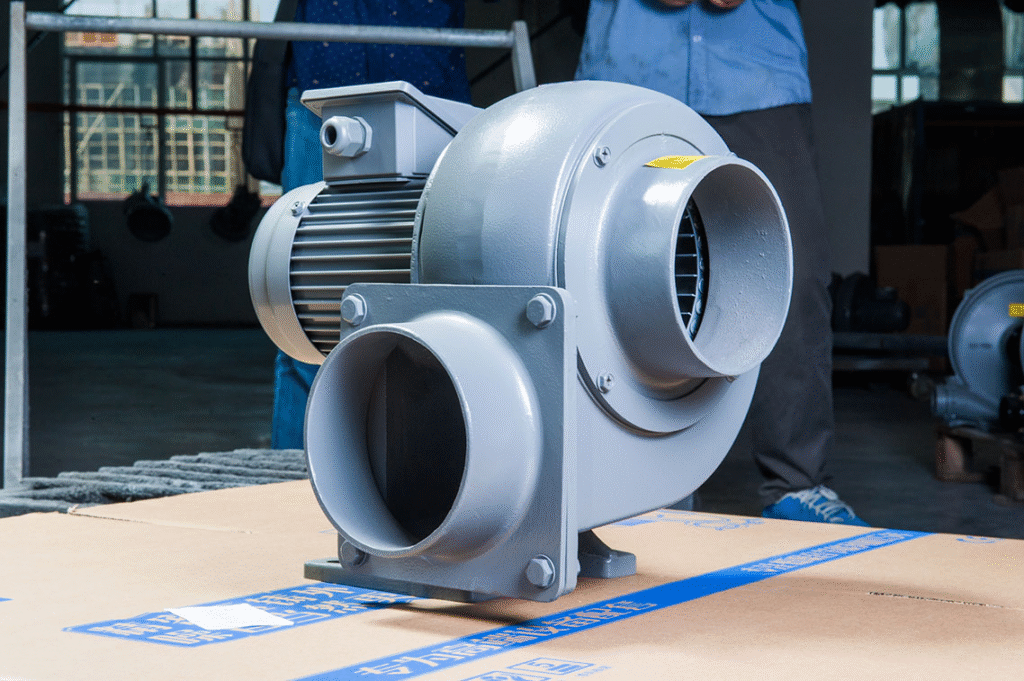

Centrifugal fans move air by drawing it into the center of a rotating impeller and using centrifugal force to push it outward through the fan outlet. This fundamental design creates a pressure increase that is inherently greater than what axial-flow fans can achieve.

The following aspects of centrifugal fan design play a pivotal role in delivering high static pressure:

The Impeller Geometry and Pressure Generation

The impeller is the heart of a centrifugal fan. Its blades, arranged around a rotating hub, accelerate air outward at high velocity. As the air is forced radially away from the center, kinetic energy is converted into potential energy in the form of pressure.

Different blade orientations—forward-curved, backward-inclined, backward-curved, radial, and airfoil—impact pressure capabilities. Radial blades and backward-curved blades are particularly effective for high-pressure applications.

The Casing or Scroll Housing Design

Centrifugal fans use a scroll-shaped housing that collects and directs the air toward the fan outlet. This enclosed structure improves compression and minimizes internal turbulence, enabling greater pressure development than open-blade axial designs.

Controlled Airflow Path and Reduced Losses

Because centrifugal fans guide airflow along a defined pathway, they mitigate many losses associated with recirculation or inefficiency. The pressure buildup occurs progressively as air moves through the impeller and casing, enabling stable output even under fluctuating system resistance.

Advantages of Centrifugal Fans in High-Static-Pressure Applications

Centrifugal fans deliver several performance advantages that make them ideal for overcoming high resistance in complex airflow systems. Engineers often choose them not only for the pressure they can create but also for reliability, efficiency, and versatility.

High Pressure Capability Compared to Axial Fans

Centrifugal fans can generate three to four times the pressure of axial fans of similar size. This makes them uniquely equipped to handle demanding applications such as filtration, fume extraction, pneumatic conveying, and industrial process ventilation.

In systems where air must be forced through filters, scrubbers, heat exchangers, or multiple duct transitions, centrifugal fans maintain the required airflow without performance loss.

Stable Performance Under Variable Resistance

High-static-pressure environments rarely remain constant. Filters get clogged, dampers close, ducts become restricted, and process loads change. Centrifugal fans help maintain consistent performance despite these fluctuations.

Their characteristic pressure–flow curve means that when system resistance increases, centrifugal fans tend to adapt without drastic changes in flow or power consumption. This stability ensures equipment downstream receives continuous airflow, which is critical in applications like dust collection or combustion air supply.

Robust Construction and Operational Reliability

Centrifugal fans are built with durability in mind. Their reinforced housings, heavy-duty impellers, and engineered bearings allow continuous operation even in harsh conditions.

This is essential in industries like:

- Foundries

- Chemical processing plants

- Wastewater treatment facilities

- Manufacturing environments with particulate loads

Because they are better suited to handle particulate-laden or corrosive air, centrifugal fans maintain efficiency and longer lifespans in these demanding settings.

Efficiency Advantages With Backward-Curved and Airfoil Designs

Modern centrifugal fans equipped with backward-curved or airfoil blades can achieve high efficiencies while generating substantial static pressure. These impeller designs reduce turbulence, minimize power draw, and deliver a favorable balance between airflow and resistance capability.

For engineers focused on sustainability and energy savings, these high-efficiency centrifugal designs are often the preferred choice for long-term operating cost reductions.

Directional Flexibility and Installation Versatility

Centrifugal fans provide numerous discharge and rotation configurations. This flexibility allows engineers to integrate them easily into complex systems where space constraints, duct orientation, or structural limitations may dictate specific mounting requirements. Such versatility is invaluable in retrofits or industrial layouts with limited space.

Key Engineering Applications Requiring High Static Pressure

Centrifugal fans are indispensable in applications where airflow must overcome significant resistance or process constraints. Their high-pressure capabilities make them suitable for a diverse array of industrial and commercial uses.

Industrial Dust Collection Systems

Dust collectors rely on fans to pull airborne particulates through filters, cyclones, and long duct networks. Because filters clog gradually and increase resistance over time, centrifugal fans ensure stable suction and airflow even under elevated static pressures.

HVAC Systems With Complex Ductwork

Large commercial buildings, hospitals, laboratories, and cleanrooms often use advanced HVAC systems with multiple bends, dampers, and filtration stages. Centrifugal fans maintain airflow under these conditions, supporting consistent air quality and climate control.

Material Handling and Pneumatic Conveying

Radial impeller centrifugal fans are particularly effective in moving materials such as sawdust, granules, or powders. The high pressure and mechanical strength of these fans allow them to withstand particulate impact and maintain flow.

Fume Extraction and Process Ventilation

In processes involving welding, chemical fumes, or toxic gases, air must be rapidly extracted through long or narrow ducts. High-static-pressure centrifugal fans provide the suction required to remove contaminants safely.

Combustion Air and Boiler Systems

Boilers, furnaces, and kilns require steady and pressurized air to maintain combustion efficiency. Centrifugal fans ensure consistent airflow against backpressure generated inside combustion chambers.

Performance Factors Engineers Should Consider When Choosing Centrifugal Fans

Although centrifugal fans offer clear advantages for high-static-pressure applications, engineers must evaluate several performance parameters to select the right model.

Fan Curve Analysis and System Curve Compatibility

A fan must match the system’s airflow and resistance characteristics. Engineers should review the manufacturer’s fan curve—which charts pressure versus airflow—to confirm the fan can handle the required pressure at operating flow rates. Matching the fan curve with the system curve ensures optimal performance and prevents inefficiency or excessive wear.

Impeller Blade Profile and Application Requirements

Different blade types serve different needs:

- Backward-curved or airfoil blades offer high efficiency and quiet operation.

- Radial blades tolerate particulate-laden air and deliver higher pressure.

- Forward-curved blades provide compactness but are typically used for lower-pressure systems.

Selecting the correct blade geometry is essential for maximizing fan performance under high static pressure.

Material Selection Based on Environmental Conditions

Centrifugal fans can be manufactured with:

- Carbon steel

- Stainless steel

- Aluminum

- Composite materials

- Specialty coatings

Harsh or corrosive environments may require upgraded materials to prevent degradation and extend fan life.

Motor Power, Speed, and Control Options

Higher static pressures demand more robust motors. Variable frequency drives (VFDs) are often used to modulate fan speed, improve efficiency, and reduce mechanical stress during start-up.

Control strategies help adapt to dynamic pressure changes in real-world applications.

Noise and Vibration Considerations

Although centrifugal fans are generally quieter than axial fans at high pressures, noise can still be a concern in indoor or sensitive environments. Engineers may incorporate silencers, vibration isolation mounts, or optimized blade designs to reduce acoustic emissions.

Why Centrifugal Fans Remain the Engineer’s Preferred Choice

The combination of high static pressure capability, durability, reliability, and efficiency makes centrifugal fans an unmatched solution for demanding air movement applications. Their ability to maintain airflow against resistance and adapt to changing system conditions ensures consistent performance where axial fans or other technologies may fall short.

Whether in industrial processing, HVAC, dust control, material handling, or combustion support, centrifugal fans deliver the pressure, stability, and operational longevity engineers require. As systems become more complex and efficiency standards continue to rise, centrifugal fans will remain integral to designs where performance under load is critical.